Heathrow asked our team at Beyond Design to help them develop a new, entry-level pipette filler that would be introduced as the economic version of their RotaFiller™ family.

Heathrow Scientific is a leading manufacturer of innovative lab supplies and instruments. A company known for producing colorful, innovative, and intuitive products, our team had to stay true to Heathrow’s image, as well as gain insight to the intended users and product applications.

Understanding the Consumer

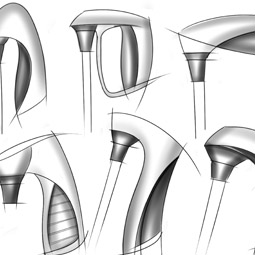

The target market for the RF1000™ Pipette Filler are students and professional adults age 15-30 (50%-60% women) that have lower budgets to work with. Through our research, we found the users were extremely concerned with the ergonomics, size, and weight of the unit. A broad range of design factors and component configurations were explored through our proprietary Strategic Design Process (SDP). Our SDP enables our team to visualize new form factors and ensure proper ergonomics. The proposed solutions concentrated on an innovative, yet smaller, design.

Incorporating Heathrow’s Commitment

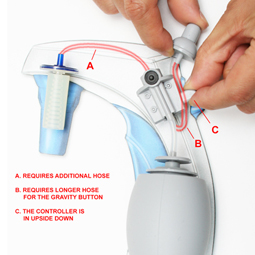

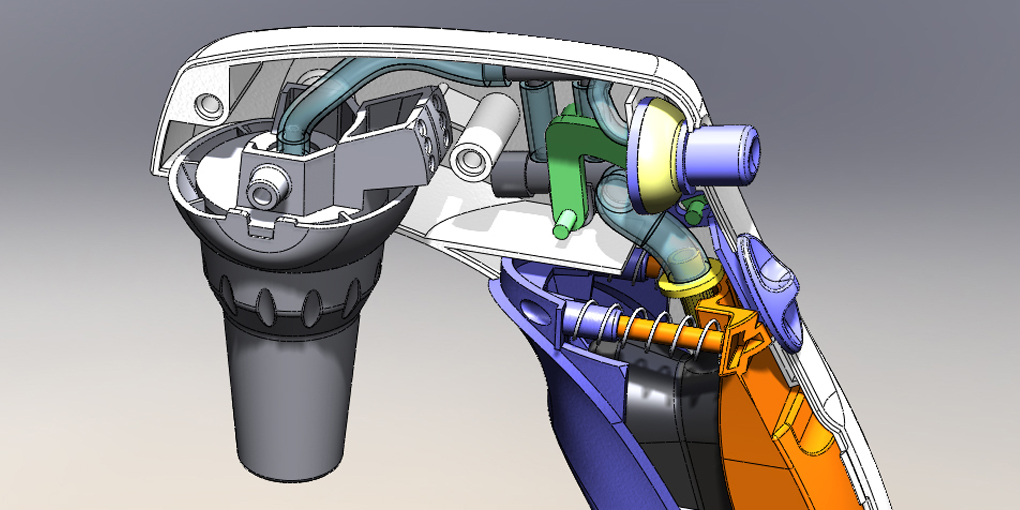

From concept to final product launch, our team was committed to designing a form that is lightweight, ergonomic and comfortable to operate. The toggle switch, used to direct airflow, is ergonomically placed and allows for one-handed operation to aspirate and dispense fluids. The instrument is extremely intuitive to operate. The introduction of translucent colors makes the unit an iconic design that is easy to distinguish among the competition. Early concepts developed in CAD were used to visualize mechanical operation and determine internal volume capacity. Through these efforts, our team was able to better evaluate functional details and implement a series of changes that improved function before construction of the working prototype. This saved time and ultimately lowered development cost.

Designing a Cost-Effective Solution

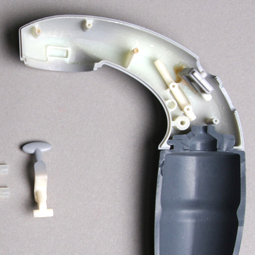

The RF1000™ Pipette Filler breaks the traditional pipette entry price point with the introduction of a high precision, yet economic, version specifically designed for educational markets. The reduction in cost was achieved by introducing a manual pump that is both aesthetically pleasing, and provides easy, one-handed operation. Internal components were carefully studied to ensure that performance and specified cost targets could be achieved. Through proper planning and material selections, designers created a working prototype to evaluate handle comfort, bulb displacement capacity, the housing, and all internal components to ensure proper fit and function before manufacturing. The final design accommodates graduated or volumetric pipettes (glass or plastic) and can be used with volumes ranging from 1mL to 100mL.

Top

Top