Developing practical and measurable solutions intended for mass production is critical for successful product development. Our team is skilled at Design for Manufacturing (DFM) and our designers and engineers work concurrently to create products that are beautiful, functional, reliable, and manufacturable. Advanced FEA and CFD tools enable our engineers to create virtual simulations to test designs, optimize performance, and determine material selections.

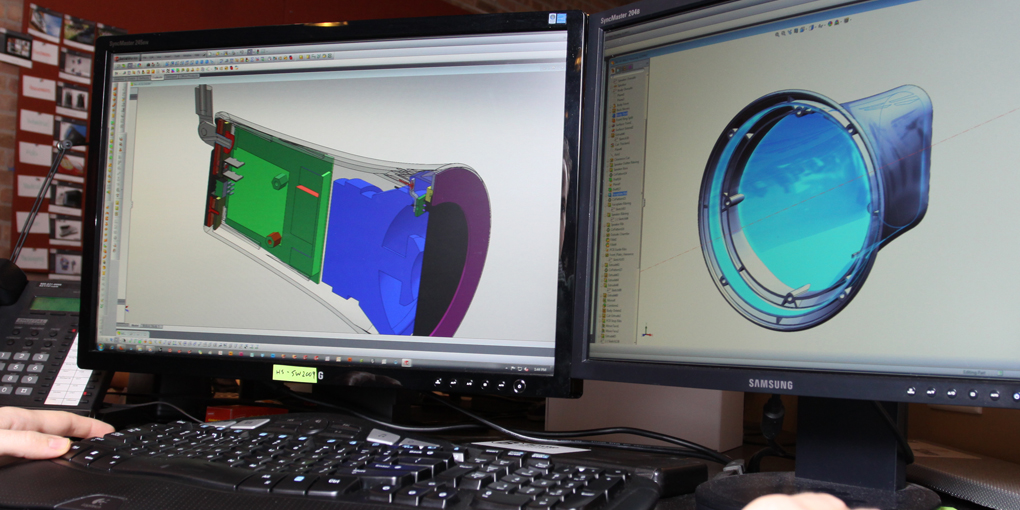

Our team is skilled in mechanical part design for manufacturing (DFM) in CAD (SolidWorks & Pro/ENGINEER) and engineering assembly accommodation. We develop part strategies and review material options and methods for manufacturing to assure quality standards and price targets are met.

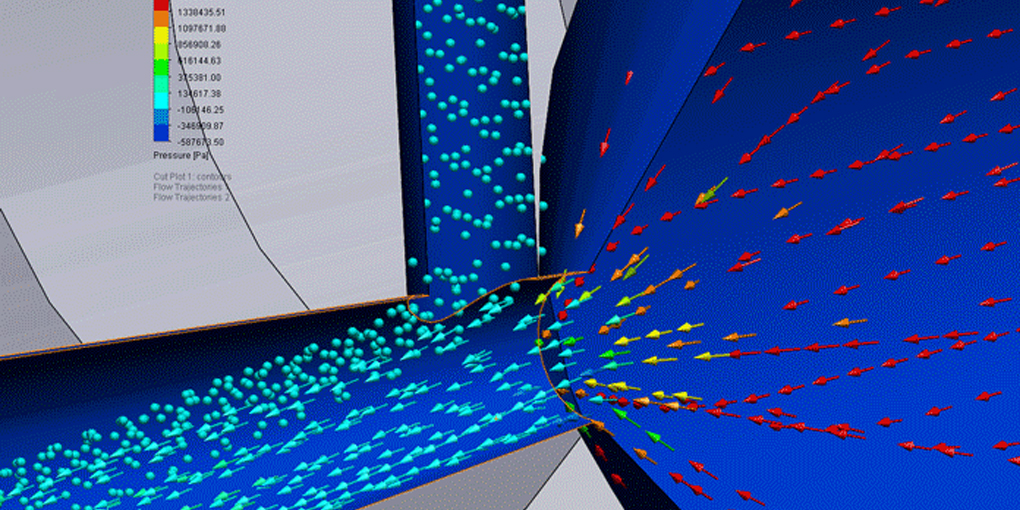

We offer Computational Fluid Dynamic studies (CFD) to test, measure, and provide the optimal fluid, gas, and thermal transfer, as well as critical FEA verification.

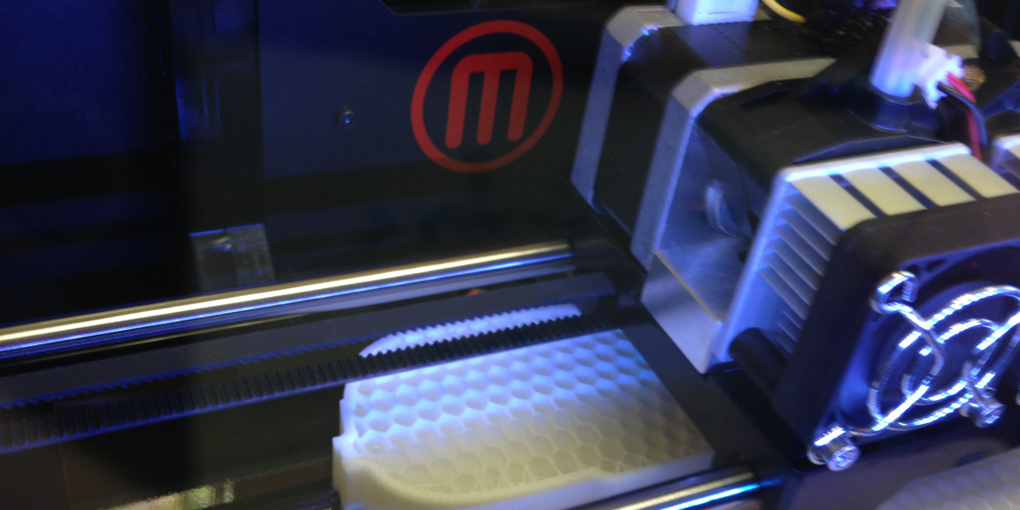

Our in-house 3D printing allows for quick onsite design verification, as well as feature validation right up to tooling production. We also manage prototypes that require CNC cutting in specific materials, vacuum forming, plaster metal casting, urethane casting, and prototype tooling.

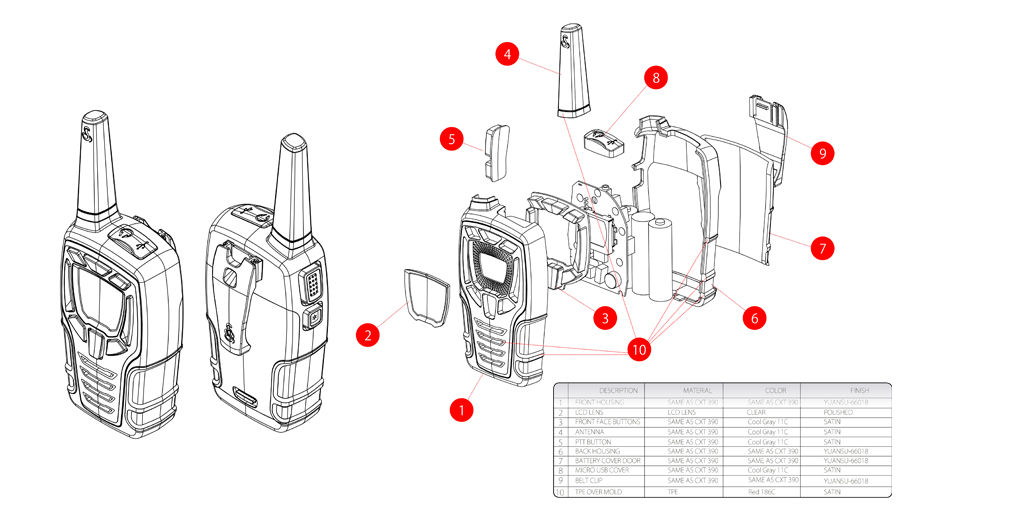

We provide manufacturing specification drawing packages, part data delivery, communication, and support for our clients as their product moves into production tooling.

Top

Top