(DFM2) A Balanced Approach to New Product Development

By: Michael Prince, President Beyond Design, Inc.

The product development process involves communication and compromise among interacting and often competing objectives from marketing and manufacturing. As experts in product development, our goal is to create a product or service that positively impacts a users life, while also ensuring that the solution is properly designed and engineered with a competitive advantage in the market.

Over the past few years we have seen dramatic changes in New Product Development (NPD) with projects focusing on solving more complex business challenges that require better planning with faster development schedules. In order to accommodate these challenges it is critical to understand the purpose each offers, and how they can work concurrently to ensure success.

We view the power of Design for Manufacturing (DFM) + Design for Marketing (also DFM) in the same light – combining these two key terms, which we refer to as DFM2 . This collaboration yields an optimal solution, with better planning throughout the entire business model.

The Value of Design for Manufacturing

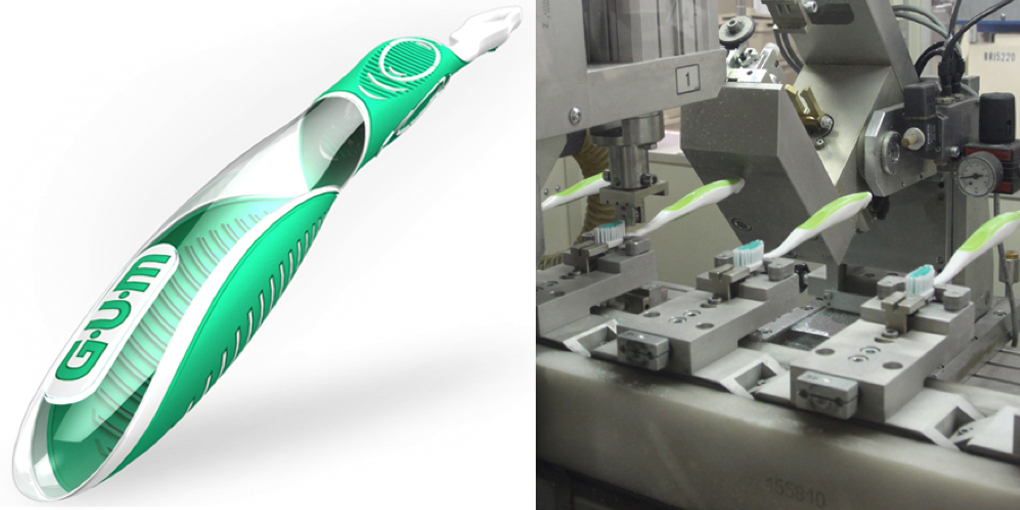

Design for Manufacturing (DFM) is part of the DNA of Beyond Design, and is present throughout our development process. A great deal of consideration to materials and manufacturing methods is discussed up front to ensure the proposed unit volumes and target costs are properly aligned.

As concepts are developed, they are evaluated not only on the merit of the idea, but also on the feasibility to execute. Industrial designers sketch ideas with an inherent nature to consider materials with assembly strategies, ensuring early concepts are properly aligned with features and anticipated cost. Prototypes are used to validate functionality and performance prior to release for manufacturing. Continued improvements are developed in CAD, providing a faster time-to-market along with precision and higher quality control. In short, DFM offers practical methods for improving designs with respect to manufacturing considerations.

Most companies incorporate DFM into their decision making process and use this to further seek cost reduction through eliminating complexity and redundancies. However, when cost outweighs the perceived value by the customer, trade offs between features and manufacturing techniques need to occur or marketing and sales will have less desirable results in the marketplace.

Understanding Design for Marketing

While it is important to understand Design for Manufacturing, it is also critical to comprehend the market landscape and have a clear vision for your product position, quality, and brand promise. Other key factors include channels of distribution and pricing, which are rapidly changing. How end-users acquire products is different from just a few years ago. People are conducting far more research and sharing personal experiences to gain confidence in a product’s performance before their purchase. Online marketing is opening new doors to both large and small companies, and it appeals to both the young and older generations – presenting completely different perspectives. The new generation is more socially connected and looking to find the newest trends, while older generations are seeking to simplify their lives and want to stick with brands that they are comfortable with and will remain loyal to.

At the start of any project, it is critical to take an in-depth look at the market and work to understand historical and potential future factors affecting a product category. We then overlay this data with a user-centered point of view and organically, but also strategically, align product strategies with the end-user needs and brand positioning. Strategic planning up front reduces time to market with better success.

Marketing is often in charge of leading product development and managing product line roadmaps. Making sure the brand promise and cost are properly aligned is the greatest challenge when developing a new product. Marketing often relies on user insights to test the waters early in the development process, ensuring features and pricing are aligned. In addition, marketing needs to work closely with manufacturing to ensure solutions can be achieved within the reasonable cost to maintain profitability. We no longer look at simply how to make something, but we also take into account why we are developing a product –what services or needs does it really solve for the end-user. We design for marketing just as much as we do manufacturing.

Introducing DFM2

For design solutions to be successful it is imperative to find the balance between making a product attractive with features and benefits, while also selecting materials and manufacturing processes that satisfy product performance and adhere to set cost.

Design for Manufacturing + Design for Marketing = DFM2 is a new term being used by product development teams to create a strong influence with solutions.

This being said, to start any project without an understanding of the marketing objectives or manufacturing options would be like playing Russian roulette. In today’s accelerated economy, companies cannot afford to fail without direct affect and consequences. Knowing the needs of stakeholders and end-users, guides us more quickly to an understanding of the design attributes that must be incorporated. Furthermore, projected quantities of a product can directly influence the materials and manufacturing methods and in turn, will directly influence the design solution. Product development is a complex puzzle that needs to fit together in such a way that all aspects of business are realized.

Case Study: US Foods

Recently, we designed the Simpull™ Touch Cutlery Dispenser for US Foods, which provides a completely new solution and user experience for the delivery of utensils. When designing the dispenser the primary marketing intent was to develop an intuitive, hygienic and onehanded dispensing solution. Development teams were able to take this further by using field research to clearly illustrate problems with current cutlery systems being used, as well as identify areas of opportunity for true innovation. Research teams interviewed a broad range of stake -holders observing user interactions as well as speaking with purchasing, stock associates, operators and endusers, each adding insight to the needs that the new delivery system should include.

Comments like “it shouldn’t be too tall” and “it has to be flexible and easy to reload,” became critical from the establishments perspective. On the other hand, end-users stated: “I want to be the first person to touch the fork,” and “I just want to use one hand to grab my utensil and not have a big mess.” Both offer different insights, and it is this understanding of DFM2 that opens the door to new opportunities and innovation. A clear understanding for the end-user and stakeholder needs dramatically helped address each component with precision.

The Simpull Touch™ Cutlery Dispenser went far beyond the intended market needs of US Foods. Unlike the competitive models, the new dispenser employs a universal reservoir mechanism that dispenses any combination of three cutlery cartridges (fork, knife or spoon) so each establishment can fill the unit to their usage needs.

Vacuum formed transport cartridges were developed to keep the utensils from being touched, and provide a convenient and sanitary way to transport large quantities of cutlery. This solution was also designed to be frontloaded, allowing for easier restocking that is faster and more convenient.

Lastly, a designer was inspired by a personal experience and was compelled to include “Braille,” to accommodate the seeing impaired. This addition to the utensil cost nothing, yet the effect it has to the end user is priceless.

The success of this program is attributed to taking a holistic and balanced DFM2 approach to fulfilling multiple stakeholder objectives from sales and marketing to manufacturing and end-users. If the program were solely focused on manufacturing, creating a solution that was hygienic, keeps a small footprint and reduces unnecessary waste may have gone unmet.

Case Study: Cobra Radio

A second project where DFM2 played a major role in determining the best design solution, was with the Cobra Walkie Talkie CX312 & CXT545 radios. Knowing that the designs had to hit aggressive price-points, it was important to develop a product strategy that allowed Cobra to have a ‘Good’ and ‘Better’ product line.

Industrial Designers suggested using common tooling and the introduction of a soft-touch material to create visual and tactile differentiation with limited increase in cost. These insights enabled our team to come up with the optimal solution that is aligned with the market needs.

With any project, understanding the end user – whether it is a surgeon, athlete, or a working single mother – provides designers and engineers with empathy and understanding of the real problems people face. If the product doesn’t fit into the consumer’s life and fill a gap, and/or the solutions created are not feasible from a business or production standpoint, then the product will fail.

While identifying production limitations allows us to create a more attainable end design, we do not believe it should limit any designer, or take away from, delivering the best possible experience to the end user.

All product limitations do, in our eyes, is fuel creativity around creating a successful solution. The concept of uniting Design for Manufacturing + Design for Marketing, or DFM2, creates a powerful combination to bring the right innovative products to market with a high rate of user acceptance and profitability.

Top

Top