The State of Right To Repair in 2025

If you look inside your phone or laptop right now, you’ll find literal treasure like gold, silver, copper, and other precious metals sitting at your fingertips. Yet when these devices break or become damaged, most of us simply throw them out and buy replacements. That throwaway mentality is just wasteful and economically backwards.

The Business Reality Behind Repair Resistance

Right to Repair simply requires manufacturers to provide owners and independent repair businesses with fair access to service information and affordable replacement parts.

Watch this quick video explaining what the Right To Repair is.

It’s funny because you are already allowed to repair anything you own. Still, the challenge is that manufacturers have built entire business models around making repairs so difficult, expensive, or impossible that buying new becomes the only viable option. From a revenue perspective, it’s easy to see the appeal. When sales depend on constant product replacement cycles, making repairs inconvenient will boost profits. This creates what we call “designed for the dump” products that are engineered to fail or become unrepairable within specific timeframes.

The math is brutally simple: if it’s easier and cheaper to discard and replace it than fix it, most consumers will prefer that option. Companies are aware of this, and they time their new product development cycles accordingly. While this model has been profitable, it’s neither sustainable nor respectful of the people who buy our products, as we’ve explored in our blog on ESG Criteria.

The Legal Landscape is Shifting Fast

The momentum behind Right to Repair has reached a tipping point. The European Union’s Right to Repair directive, passed in July 2024, takes effect in July 2026 and will mandate manufacturers to provide product documentation, parts, and tools to consumers or independent repair representatives.

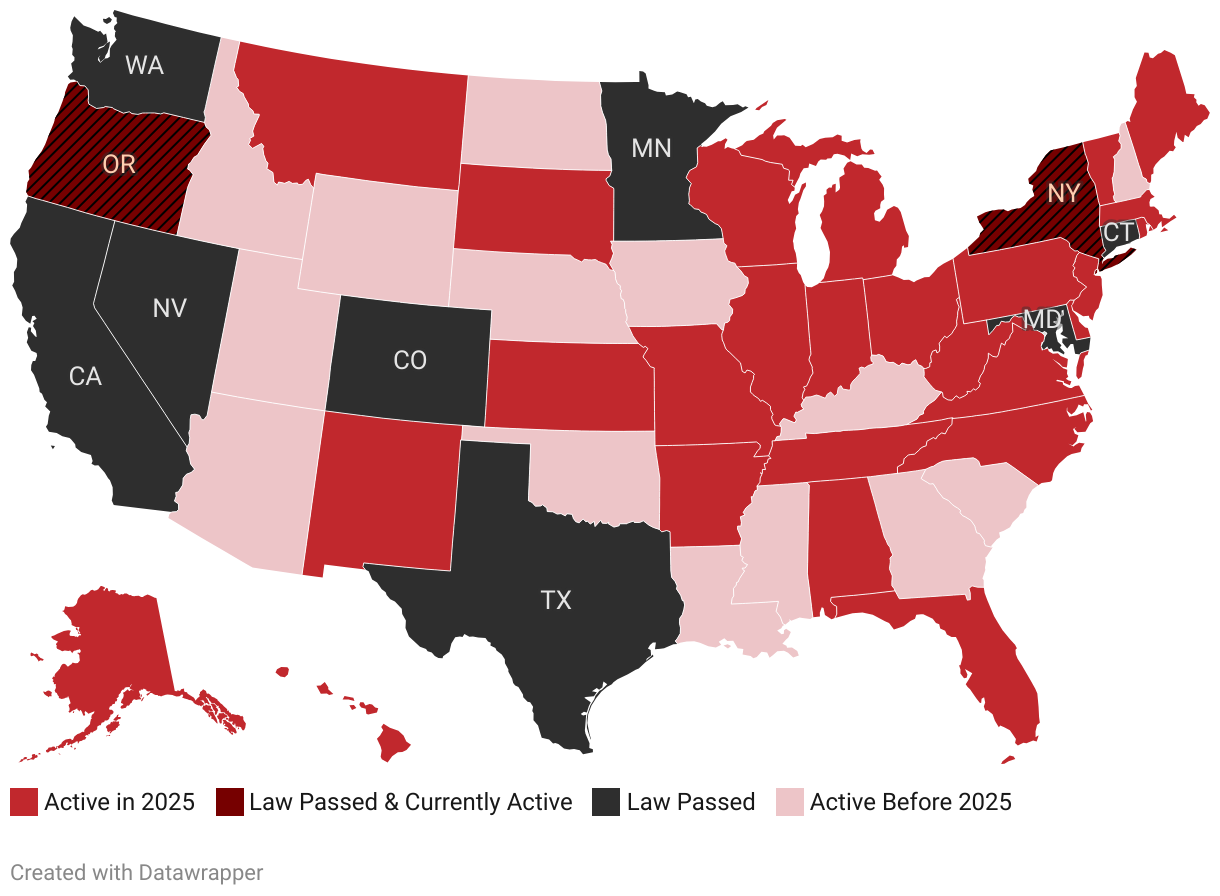

In the United States, we’re witnessing remarkable legislative activity. Maine passed automotive Right to Repair legislation in 2025 to even the playing field for small and local repair businesses. The law gives them access to the same diagnostic information that manufacturers use. Additionally, Colorado and Oregon have banned “Parts Pairing” practices, and legislation has been introduced in all 50 states (iFixit.com).

Visual of the introduced US legislation created by the Right To Repair Association

Illinois, our home state, is considering the Fair Repair Act (Bill Status of HB2549, which would require manufacturers to provide independent repair shops and authorized dealers with repair tools, parts, software, and documentation on fair terms. Set to take effect July 1, 2025, the law seeks to expand repair options, extend product lifespans, reduce costs, and cut down electronic waste. Shops must disclose if they’re not authorized or using non-original parts, and manufacturers won’t be liable for damage from independent repairs. Exceptions exist for companies offering free replacements, with penalties for noncompliance.

The Parts Pairing Problem

One of the most insidious barriers to repair is a practice called “parts pairing.” Companies assign unique serial numbers to individual components that the device can detect, like screens, batteries, and sensors. When original parts are replaced, even with identical components, the device intentionally limits functionality due to the “unauthorized” swap.

John Deere takes this to the extreme by rendering replacement parts useless unless installed and approved by licensed technicians. With few certified specialists, farmers face repair delays that cost them valuable time, money, and crops. Rights To Repair legislation would eliminate this problem and benefit consumers.

Example of a “No User Serviceable Parts Inside” warning label.

This is more about control than safety or security. Comprehensive Right to Repair legislation would eliminate these artificial bottlenecks and restore consumers’ ability to maintain their property. Companies typically fight back with claims about safety and cybersecurity risks, or concerns about liability for third-party repairs. While these sound reasonable on the surface, they don’t withstand scrutiny. For example, the automotive industry has operated with independent repair shops for over a century without catastrophic safety failures. Additionally, medical device manufacturers already provide repair manuals and parts to hospitals. The real concern should be user safety, not protecting lucrative service monopolies and planned obsolescence strategies.

Solutions Are Already Working

While we wait for comprehensive legislation, grassroots solutions are proving that repair-friendly approaches work. Over 2,500 cities worldwide now host Repair Cafes, community-led spaces where people share knowledge and fix products together. These initiatives directly oppose throwaway culture and help consumers extend the lifecycles of their products. (Find a Repair Cafe near you at repaircafe.org). And for those who don’t live near a Repair Cafe, there are resources like iFixit.com that also provide detailed repair guides and parts, demonstrating that when information and components are accessible, people will choose repair over replacement. The demand is there; it’s just that the barriers are artificial.

Repair Cafes are lively and helpful in many cities worldwide, as seen by this picture of one in France.

On a larger scale, forward-thinking companies are adapting too. Apple launched a DIY repair program, while Google and Samsung now sell parts directly to consumers. These moves are good, repair-friendly approaches to build customer loyalty and create new revenue streams, but isolated efforts won’t be enough to create lasting change. The next step towards a Universal Right To Repair is creating systemic solutions.

What This Means for Product Leaders

Products designed for longevity and repairability can command premium pricing, reduce warranty costs, and create ongoing relationships with customers beyond the initial sale (an approach we broke down in our blog on Why Product Longevity Is the New Luxury). The companies that embrace this shift early will gain more user trust and have competitive advantages as Right to Repair laws become more comprehensive.

What Right to Repair laws change is stopping manufacturers from intentionally preventing or derailing user repairs, and also mandating that manufacturers provide a clear way to do so. The 2025 legislative landscape shows us that change is inevitable. The question isn’t whether Right to Repair will become standard or if companies will lead this transition or be dragged through it by regulation.

For those of us in product development, this represents a fundamental shift in design philosophy. Instead of optimizing for planned obsolescence, we need to optimize for longevity, modularity, and user empowerment. The precious metals in our devices are just the beginning; the real treasure is building products that respect both our customers and our planet. To fix everything, we need to fix the system itself, starting with how we think about, design, and consume products.

Top

Top