The Guide to Professional 3D Printing

Remember when you were a kid and wished you could imagine anything as if it were real? That feeling comes to life with modern 3D printing. 3D printing is a game-changer for Beyond Design and how we bring ideas to life. So, we’re excited to share The Guide to Professional 3D Printing.

What Is a 3D Printer?

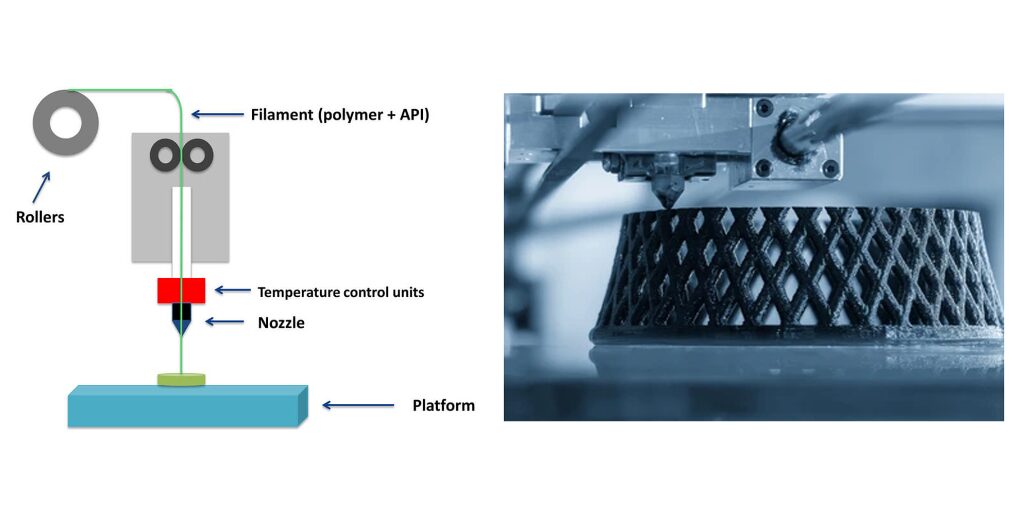

Let’s start with the basics of 3D printing. Think of a 3D printer as building a sandcastle, but with melted plastic instead of sand. The printer lays down thin layers of plastic, one on top of another. Each layer hardens and sticks to the one below it, and by stacking hundreds of layers, the printer creates a solid 3D object. That’s the essence of 3D printing.

The technical term is ‘additive manufacturing’ because the process builds objects layer by layer—like stacking the world’s tiniest bricks. It starts with a CAD design created on a computer, which can be anything from a prototype to a custom part to any object we can digitally conceive. Once we send this file to the 3D printer, the machine interprets it and deposits material layer by layer, transforming the digital design into a physical object.

Why 3D Printing Changes Everything for Design

Our 3D printers are running constantly. Here’s why they’re essential for industrial designers:

Speed- We can design something in the morning and hold it by afternoon; No more back-and-forth shuffling with manufacturers, prototype shops, or expensive tooling makers. We can work in-house faster to iterate quickly and perfect designs before production.

Freedom- We can build prototypes with bold experimentation. When each version costs a few dollars in material, we are free to test wild ideas that lead to breakthrough solutions. This freedom lets designers examine unique concepts that might otherwise never leave the sketchbook.

Real-world testing- Screen models and flat drawings can be misleading. You can’t know if something feels right, fits properly, or works until it’s physically in your hands. We’ve saved countless projects from making costly mistakes by catching design flaws early on in the process through printed prototype testing.

Better client collaboration- Handing someone a physical prototype they can touch and turn over transforms abstract conversations into concrete ones. Clients can have a better understanding of the design and provide clearer feedback when reacting to something tangible.

The Printers We Recommend

Not all 3D printers are created equal. If you’re considering getting into 3D printing, here are our top recommendations that we use in-house for different needs:

For beginners – Bambu Lab A1 Mini ($299): A great starter printer. Its plug-and-play design is simple, incredibly reliable, and produces excellent quality prints. The learning curve is minimal, perfect for beginners who want to understand the basics of 3D printing.

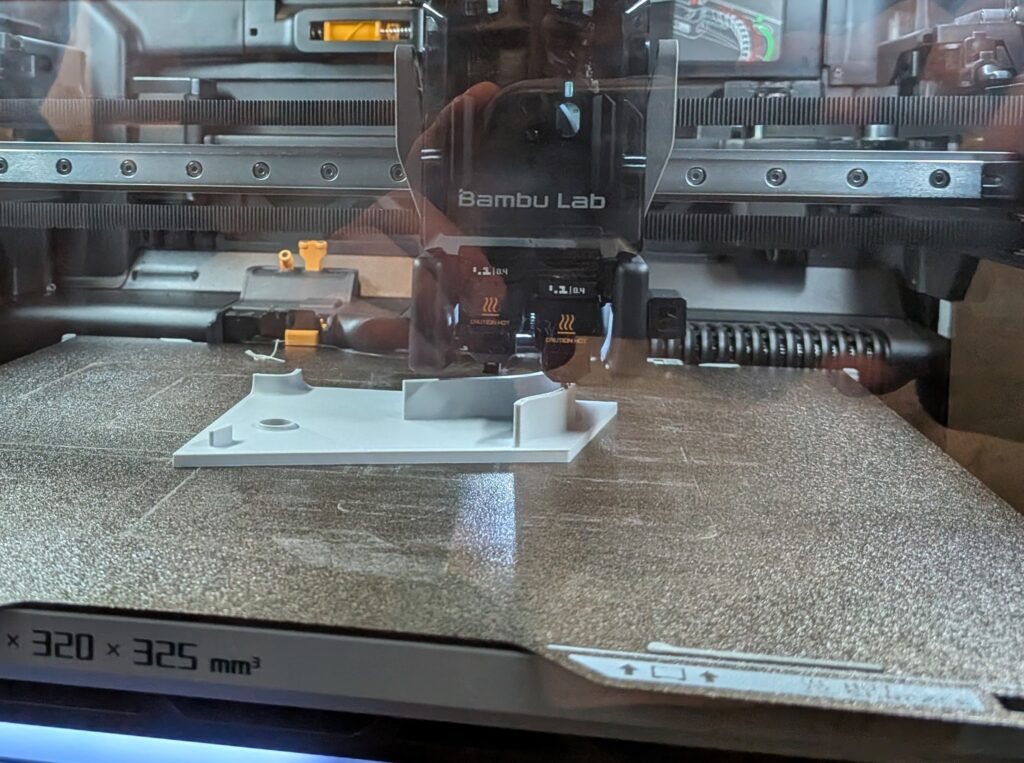

For serious prototyping – Bambu Lab X1C ($1,199): It’s fast, accurate, and handles a wide variety of materials. The multi-filament capability means we can print prototypes with different colored or materialized sections in a single print job to show where different parts or materials meet in a design. The fully enclosed chamber also means we can print advanced materials that require controlled temperatures. Great for sturdy print jobs.

For fine detail work – Anycubic Photon M3 Max ($1,099): A SLA resin printer, which works differently from the filament printers above. Instead of extruding melted plastic, it uses UV light to cure liquid resin layer by layer. This means incredible detail down to the most miniature features at 7K print resolution and smooth surface finishes that filament printers struggle to match. If you are looking for smooth and seamless print quality, this is the machine for you.

For larger prints – Bambu H2D ($1,999): Our studio workhorse. Built for big projects with its large print volume, it’s perfect for creating full-size prototypes or larger components in one piece. It offers dual-extrusion printing, allowing for multi-material or multi-color parts, and maintains excellent precision even at its scale. This is our go-to when we need large, durable prints without compromising quality.

Filament Is the Unsung Hero

Many 3D printing novices get tripped up regarding different types of filaments. Filaments are to a 3D printer what ink is to a paper printer. It’s your raw material that can transform into anything from a spool of plastic wire. Here’s some basic information about filaments and how they impact 3D printing:

Why does filament choice matter so much? Different filaments have wildly different properties, and choosing the wrong one can mean the difference between a successful print and a failed mess. When 3D printing, you must use the right material to match your project’s needs.

PLA (Polylactic Acid) is where everyone starts. It’s easy to print, eco-friendly (made from cornstarch), and produces great results. The downside is that it’s not heat-resistant and will warp in hot conditions. We use it for visual prototypes and concept models, where stress or heat endurance isn’t necessary.

PETG (Polyethylene Terephthalate Glycol) offers a practical combination of properties. More durable and heat-resistant than PLA, it’s the same material used in water bottles—making it ideal for functional prototypes that will be handled repeatedly, dropped, or exposed to weather.

ABS (Acrylonitrile Butadiene Styrene) is tough as LEGO bricks (literally, that’s what they’re made from). It handles high temperatures and serious abuse, but it’s finicky to print and requires ventilation due to fumes. We use it for end-use parts and prototypes that need real-world durability.

TPU (Thermoplastic Polyurethane) is flexible and rubbery, akin to 3D-printable silicone. We use it for gaskets, phone cases, and any object that needs to bend or compress. It’s tricky to print because the filament itself is flexible, which can cause jams.

Quality Matters. The quality of your filament matters as much as the type. Cheap filament might save you a few dollars, but inconsistent diameter, moisture absorption, and impurities will cause failed prints and endless frustration. We stick with reputable manufactured brands for our filament purchases to keep things simple.

What To Do Post 3D Print

Your print is done, but the work isn’t quite finished yet. Most 3D prints need some cleanup to look and function their best.

First up is support removal. Most prints require temporary scaffolding structures to hold up overhanging parts while printing. These supports look like messy lattices underneath your object. Use pliers to carefully snap them off, working slowly to avoid damaging your actual part.

Next, you’ll deal with surface cleanup. Layer lines and rough spots can be smoothed with sandpaper. And if you want a really polished look, spray primer hides layer lines beautifully and prepares the surface for painting. Multiple thin coats of paint always beat one thick coat.

The secret most beginners don’t realize is that not every print needs extensive finishing. A quick test prototype doesn’t require sanding and painting since its job is just to check if the design works. Save the detailed finishing work for presentation models and final prototypes. The goal isn’t perfection every time; it’s making your print fit its purpose.

Removing the Friction From Innovation

3D printing has advanced design in ways we could only have imagined when we started Beyond Design over 30 years ago. What once required expensive machinery, specialized facilities, and weeks of lead time can now transpire overnight in-office..

3D printing is a tool that helps our designers maintain creative momentum and iterate on ideas constantly. We work in cycles of days instead of months, test ten versions instead of debating one, and put prototypes in clients’ hands at the first meeting instead of the fifth. The technology removes friction from creativity, leaving more time for what matters: solving problems beautifully, pushing ideas further, and creating things that improve lives.

That’s why design matters. And that’s why 3D printing matters to design

Where 3D Printing is Headed

The 3D printers in our studio are impressive, but they’re just the beginning. The technology is expanding into areas that seemed impossible a decade ago.

Construction companies are now printing entire houses layer by layer, using concrete instead of plastic filament. The same technology being developed for affordable housing on Earth is being adapted for building habitats on Mars and the Moon, places where there isn’t exactly an abundance of construction crew labor.

For product designers, this means the barriers keep dropping. Materials continue to improve, printers are faster and more precise, and costs are more affordable. What required industrial equipment five years ago now sits on desks. We can explore ideas that were too expensive or technically impossible pre-3D printing. Now, with the technology, we can have prototypes printed and ready on command.

The real revolution for us isn’t building on Mars. It’s how designers can have an idea in the morning, print it by lunch, and test it before dinner. Small companies can compete with corporations because prototyping no longer requires massive capital investment. We fail cheaply and often, which leads to better final products.

3D printing hasn’t replaced traditional manufacturing for mass production, but it’s eliminated the gap between imagination and physical reality. That’s why understanding this technology matters if you’re bringing a product to market.

Want to see how 3D printing could accelerate your next project? Reach out to our team at Beyond Design!

Top

Top